-

Aluminium Centrum

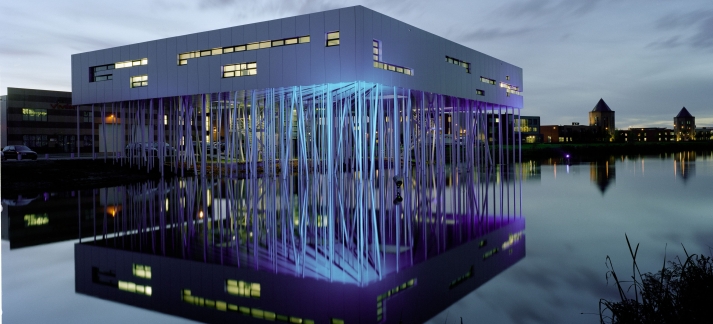

Few buildings evoke the universal response ‘how on earth does it stand up?’ but the Aluminium Centrum in Houten, the Netherlands, is one of them. A flat simple slab of a building (although not as simple as it first looks) is supported on the slenderest possible of supports coming up out of the water. On a day when the light is right, with reflections in the still water, the effect is of the tentacles of a jellyfish – not the most structurally rigid of concepts.

Architect Abbink X De Haas architectures (Micha de Haas) Location Houten - The Netherlands Company involved 3A Composites Website http://www.3acomposites.com

In one sense, the answer to this conundrum is simple. We are used to buildings being supported on a relatively small number of large structural members. At Houten, architect Micha de Haas of Abbink x de Haas, has taken the opposite approach, supporting the building on an immense number of closely spaced members.

‘One of the main ideas is that you can’t believe it stands up,’ explained de Haas. ‘The question was to design a building that represents the qualities of aluminium. It is both strong and light.’ The building is a centre for exhibitions and information about aluminium, and therefore had to use the material wherever possible and act as a showcase for its properties.

For the supporting structure, de Haas was inspired by the idea of a forest of birch trees, with its numerous slender silvery trunks set close together. ‘With columns,’ said de Haas, ‘we are always searching for the largest possible span. We said, what if we look for the smallest possible spans?’ The next association, he said, was ‘with a bed of needles, or an Indian fakir’. The structural idea, explained de Haas was ‘that if you reduce the span of the columns, you can reduce their diameter, and also the thickness of the floor’. Spans range from a mere 60cm to 3m, and the diameters of the columns from 90mm to 210mm. The columns are aluminium tubes, about 6m high. Originally the team looked at using even slenderer columns and in terms of simple structural support they could have worked. There would however have been issues with vibration in the wind.

This all had to be worked out from experimentation and from first principles. ‘There were no calculations available,’ de Haas explained.

He added ‘the structural idea was to see if you could reduce the span between columns and reduce the thickness of the floors.’ The entire structure is of aluminium, with aluminium trusses that are glued not welded or bolted together. ‘There is quite a lot of technical innovation on this building,’ de Haas said.

The building is only single storey, but de Haas did not want this to be obvious from the outside, so he has played with the pattern of fenestration to give the impression that there are two floors. With strips of windows at varying heights, coupled with the fact that the building sits in the water with no immediate neighbours for a sense of scale, one has the impression of two storeys.

There is another surprise once one gets inside. Designed like a doughnut, the building has a hole in the middle. The effect from inside is of looking into a courtyard, but this is one to which there will never be public access, since it has no floor but drops directly to the water below.

Since aluminium is a lightweight material, this was never going to be a building with a great thermal mass. Instead, it celebrates its lightness, and the fact that it can respond quickly to heating or cooling.

Cladding is with composite panels from Alucobond, consisting of approximately 4mm thick sheets of aluminium, and which a composite core. In contrast to the columns, which are in anodised aluminium, the cladding is coated with a metallic finish. The roof is of profiled aluminium from Kalzip, and is powder coated in a metallic colour.

In this way, the building is a showcase for a range of effects that can be achieved with aluminium. And with its show-stopping appearance, it is a great showcase for the material and its own advertisement. There are bigger and more complex buildings by the dozen – but few that are so jaw-droppingly surprising.